Aluminum Skylights

WITH SO MANY CHOICES

THE SKY IS THE LIMIT

Our Skylight Builder takes you through each step of the design process, to build the skylight you have been dreaming of for your home or business.

Fixed

We offer fixed skylights in virtually any size and can accommodate a wide range of configurations, including single slope, pyramids,  segmented radius domes, barrel vault, hip end, glass roofs, roof lanterns, and more. Our skylight systems can attach to virtually any substrate and are suited for both residential and commercial applications without size or design limitations.

segmented radius domes, barrel vault, hip end, glass roofs, roof lanterns, and more. Our skylight systems can attach to virtually any substrate and are suited for both residential and commercial applications without size or design limitations.

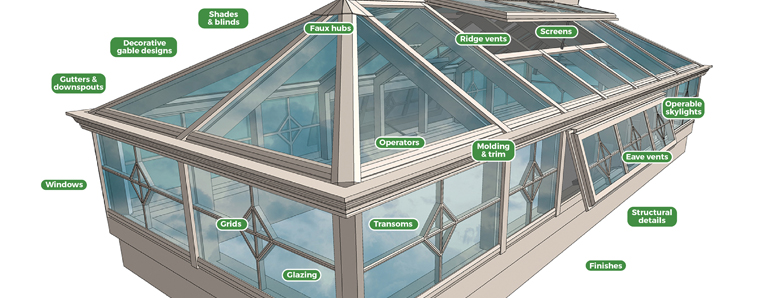

Roof Lanterns

Solar Innovations® provides the finest aluminum roof lanterns available in the industry today. Initially popular in the Victorian, Edwardian, and Georgian eras, roof lanterns can add an exciting feature to any location. Roof lanterns are a daylighting architectural element that are located atop a roof to provide a natural lighting element to the space below.

eras, roof lanterns can add an exciting feature to any location. Roof lanterns are a daylighting architectural element that are located atop a roof to provide a natural lighting element to the space below.

Venting

Venting skylights are used to bring fresh air and circulation into a room and operate with the use of a continuous hinge, similar to a ridge vent’s function. A venting skylight has a higher profile than that of a ridge vent and offers better air and water performance along with a higher thermal value.

is typical of many other industry skylights. This design minimizes the chances of long term water penetration through the sill pan.

is typical of many other industry skylights. This design minimizes the chances of long term water penetration through the sill pan.