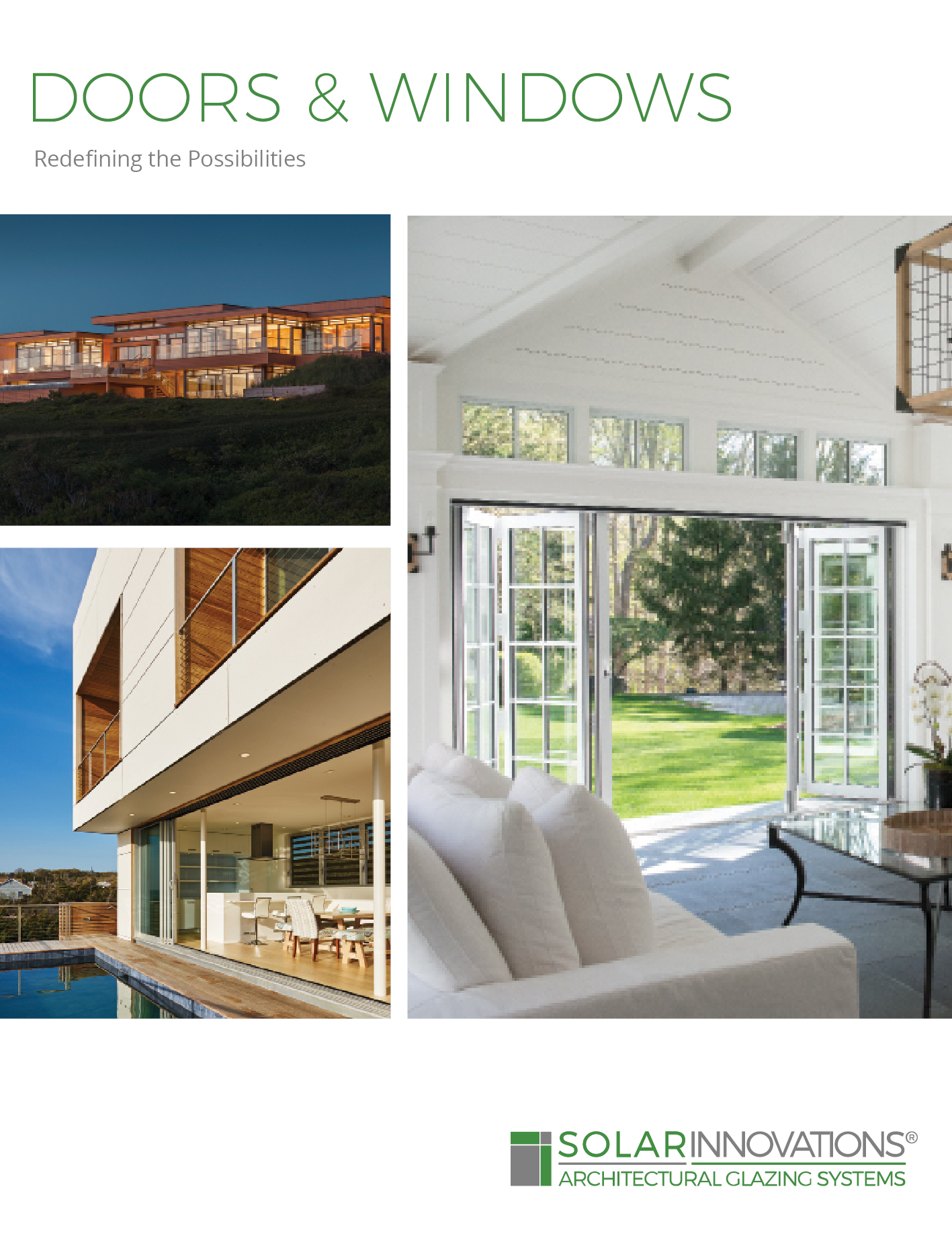

Seamless Walls with Uninterrupted Views

Our clear glass walls create a clean and seamless wall with uninhibited views. The unit’s non-thermal design makes it a great choice for interior room dividers, but Solar Innovations® can engineer the clear glass wall for exterior use as well, making it an ideal product selection for stadium suites. Panels are typically top hung, however, bottom load sliding options are also available.

Solar’s clear glass walls can be designed to operate with multiple configurations. The non-thermal clear glass walls are typically used for interior and light exterior applications. No vertical frame is required, but Solar Innovations® offers mono seal and dual-seal insulating frames that are recommended when the clear glass wall system will be utilized for outdoor applications.

Residential Applications

Whether used as a room divider or to let in natural light to your home, clear glass walls can be another perfect solution for achieving those uninterrupted views. Our glass to glass style is perfect for indoor dividers that will give the feel of an open floor plan while still providing designated space for each room. With the narrow profile frame style, you can have indoor or outdoor privacy to your space while still creating those desired views.

Commercial Applications

With seamless and uninhibited views, the clear glass wall systems are excellent solutions to any commercial need. Business owners can benefit from the sleek and modern design, all while offering customers a clear view of products. If your stadium, restaurant, or office could benefit from these walls, know that Solar offers both mono and dual seal insulating frames to ensure the longevity of your product.

Glass Options

- Glass with Narrow Profile Frame: This style has a narrow metal frame on the verticals, the top, and the bottom of each glass panel. This is best used for outdoor applications since it helps to prevent sound, air, and water transmittance.

- Glass to Glass: In this style, the glass edges are completely exposed and there is no vertical framing. Sound, water, and air can still pass through the gaps, so this is typically only recommended for interior use.

- Glass with Gasket: Gaskets are attached to the vertical sides of each panel so that when the wall is closed, it helps reduce any sound/air/water transmittance.

PLEASE NOTE: All hardware is subject to vendor availability. Custom finishes may be available upon request at additional lead time and/or cost. Solar Innovations® reserves the right to discontinue any hardware option at any time.

Paint

STANDARD – AAMA 2603*

SI Black

SI White

SI Sandstone

SI Natural Clay

SI Bronze

SI Hartford Green

Powder Coat Solids

STANDARD – AAMA 2605§

Black

FRSL 11618

White

FRSL 83247

Sandstone

FRSL 46647

Natural Clay

FRSL 47591

Bronze

FRML 97138

Hartford Green

FRSL 32872

Anodized

Additional cost

Class 1 Clear Anodized

Dark Bronze Anodized

Powder Coat Solids

PREMIUM – AAMA 2605§

Apollo White

FRSL 82908

Bone White

FRSL 82909

Ivory

FRSL 46646

Charcoal

FRSL 74654

Military Light Blue

FRSL 21709

Burgundy

FRSL 62496

Seawolf

FRSL 46645

Fashion Gray

FRSL 74652

Colonial Gray

FRSL 74653

Antique Bronze

FRSL 46648

Wood Veneering (Unfinished)

STANDARD¶

Douglas Fir

White Oak

Walnut

Mahogany

Wood Veneering (Unfinished)

PREMIUM¶

White Pine

Pecan Pine

Cherry

NOTE: WOOD VENEERING IS FOR INTERIOR APPLICATIONS ONLY. AVAILABLE ON A LIMITED BASIS DUE TO VENDOR SUPPLY.

Wood/Glulam

STANDARD¶

Red Oak

White Ash

Hard Maple

White Oak

Wood/Glulam

PREMIUM¶

Douglas Fir

Cherry

Sapele Mahogany

Walnut

*5 year warranty (finishes available while in stock).

†5 year warranty. Scratch & fade resistant; contains no VOCs. Lead times subject to availability.

§10 year; up to 20 year warranty. Scratch & fade resistant; contains no VOCs. Lead times subject to availability.

¶Lead times subject to availability.

‡Special order.

PLEASE NOTE: Depending upon color selection, additional charges and increased lead times may apply. Extended warranties and service plans are available for an additional charge. Examples are shown as accurate as photography and printing processes allow. Final finish selection should be made from a physical sample; contact Solar Innovations® for samples. Product and finish options are subject to vendor availability. Solar Innovations® reserves the right to discontinue any option at any time without notice. Additional options, including custom color match, are available; contact Solar Innovations® for details.

CASE STUDY: BRIGHT, WELCOMING PRODUCTS FOR A FINANCIAL INSTITUTION

When designing a new branch of the Savings Bank of Walpole, Bensonwood—a custom designer/builder based in Walpole, NH—approached Solar Innovations®. They were in need of a manufacturer for a glazed entryway and interior dividing walls for the bank.

CASE STUDY: CLEAR GLASS WALLS KNOCK IT OUT OF THE PARK

When designing a stadium suite at the Great American Ballpark, home of the Cincinnati Reds, a client approached Solar Innovations® for a custom clear glass wall. The glass wall would be located on a higher level and was designed as a high-class bar and lounge area for executives.

CASE STUDY: RETAIL SPACE THAT SAVORS IN THE CLEAR VIEW

When designing a new retail store for McCormick World of Flavors, a glass company approached Solar Innovations® about the job. The company was in need of a manufacturer for a glass entryway into the store that not only would offer clear, unobstructed views, but would also add security.

TESTIMONIALS

“I hope all is well. I wanted to let you know that the project went very well. We were all very happy with the quality and the very easy installation-friendly design of the doors. We were able to install the door without any issues or complications due to both quality workmanship in its fabrication and the smart design.”

Benjamin Mendible, Vista Impact Windows & Doors, Coral Gables, Florida

“Just wanted to drop a quick note of THANKS! Everything worked out well on the project. Good support on your end and easy to order, very well crated and labeled. Straight forward installation.”

JT Foody, Christopher Glass & Aluminum, Inc. , Chicago, Illinois