Mixed-Mode Ventilation Systems

The average American will spend up to 90 percent of their time indoors, while the average student spends about 15,000 hours in indoor class before their high school graduation. The COVID-19 pandemic, along with other world events have forced many, especially the most vulnerable in society, to spend nearly 100 percent of their time indoors.

Indoor Air Quality (IAQ) has been linked repeatedly to performance in school, productivity, health, and happiness. Poor air quality, caused by a lack of ventilation, can create an environment where disease is likely to cultivate, while also being generally uncomfortable for occupants. With expanded regulations applied to businesses during the COVID-19 pandemic, many business owners and decision-makers found themselves scrambling to make their locations as safe as possible.

The three primary types of ventilation used in both residential and commercial structures are natural, mechanical, and mixed-mode.

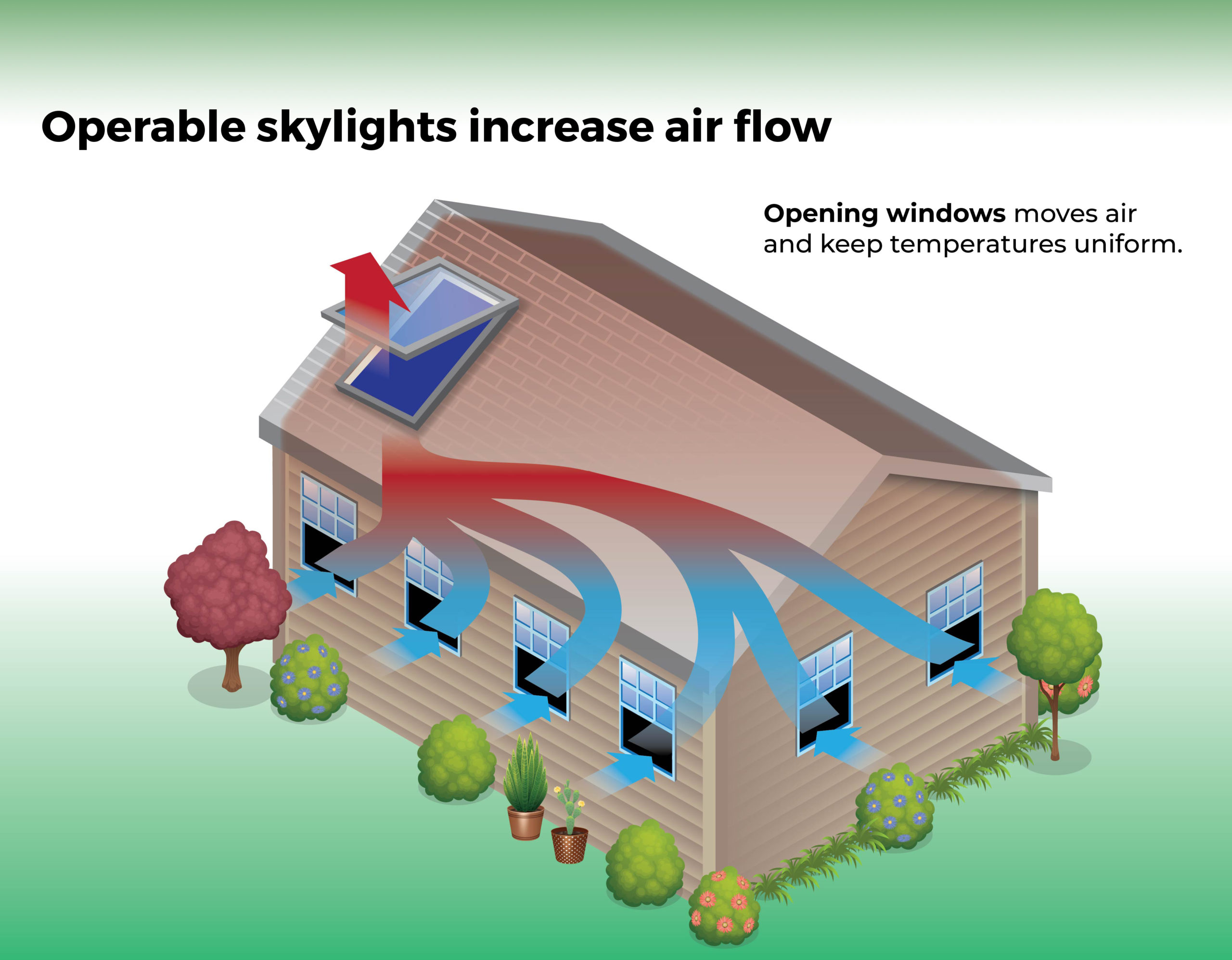

Natural ventilation, also known as passive ventilation, is the most primitive and least complicated method. Opening windows, doors, and skylights to create air flow utilizes no automation and allows the occupant to be in control of the air flow. However, natural ventilation provides very little control over temperature or humidity regulation in extreme climates. Temperature, wind, and rain sensors can be installed to reduce the need for human intervention in natural ventilation systems. Natural ventilation is the most cost-effective method of ventilation because it does not require large amounts of electricity or the installation of mechanical systems.

Natural ventilation in both commercial and residential structures can take two forms: cross ventilation and stack ventilation. Cross ventilation is created by opening windows and doors to create the movement of air through a structure. This is excellent for creating air flow, but is not very effective at removing heat. Stack ventilation occurs when lower openings and higher openings work in tandem to allow cooler, fresh air to be drawn into a space while warmer, stagnant air escapes through the higher opening. Using ridge vents with eave vents or skylights with windows are two simple ways to achieve stack ventilation.

Mechanical ventilation, often referred to HVAC systems, comes in three forms: exhaust-only, which uses a fan to remove stagnant air from the structure; supply-only, which uses a fan to bring fresh air into the structure; and balanced ventilation, which uses fans to bring fresh air in at the same rate as fans draw out stagnant air. Many structures, even those built before it became standard practice for a balanced system have been outfitted with some variation of a balanced ventilation system.

Mixed-mode, or hybrid, ventilation uses a combination of natural and mechanical ventilation to draw fresh air into a building while keeping the temperature at a level that is comfortable for the occupants. To conserve energy and maximize the effectiveness of both natural and mechanical ventilation, a Building Automation System (BAS) will be utilized to determine the most cost-effective strategy for a given time and climate. Mixed-mode systems can often be more cost effective than full mechanical ventilation systems because they take advantage of outdoor air.

Mixed-mode and natural ventilation systems require a whole-building approach, and with the advancement of computer-assisted design, such as Integrated Project Delivery (IPD) and Building Information Modeling (BIM), the whole-building approach is becoming increasingly feasible and utilized.

Benefits of Mixed-Mode Ventilation Systems

Residential

- Removal of excess moisture, smoke, odors, pollutants, and gasses from the indoor environment.

- Control of excess attic heat and crawl space moisture.

- More productive home-workplace environment.

- Greater personal comfort and satisfaction.

Commercial

- Increased employee productivity of up to 18 percent.

- Increased job satisfaction and happiness among employees.

- Removal of excess moisture, smoke, odors, pollutants, and gasses from the indoor environment.

- Reduced symptoms of Sick Building Syndrome (SBS) by 65% or more.

- Reduced energy costs of up to 80 percent, depending on climatic conditions.

Components of Mixed-Mode Ventilation Systems

A mechanical HVAC system, linked to a Building Automation System, combined with openings in the building’s envelope, is what is needed for a mixed-mode ventilation system.

Openings can come in four forms:

- Windows: Thermally-efficient windows can create energy savings and allow for cross ventilation with ease. These can include hopper, awning, casement, tilt-turn, folding, sliding, and stacking windows. Internal transom windows can help to move air between rooms effectively.

- Doors/Operable Walls: Large openings allow fresh air to circulate. The type of doors/operable walls utilized include folding, sliding, stacking, lift slide, swing, and pivot doors. Internal walls can be strategically placed to force air into desired areas of the building.

- Skylights: Varying types of operation can allow for optimized air flow and reduce drafty conditions while removing stagnant air. These can include 80-90 degree, venting, and retractable.

- Vents: Ridge vents, placed at the upper-most point of a pitched roof, will allow hot air to escape a building as it rises. For greater circulation, incorporating eave vents, placed at the point of a building where the wall meets the roof, will draw in fresh, outdoor air, that will then circulate out the ridge vent.

Opening operable windows, walls, skylights and vents can be performed in three ways:

- Manual: Performed with handles or manual cranks, this limits the maximum size and accessible locations for a system and relies on human intervention in the event of external factors.

- Motorized: This uses a thermostat or remote operation. Human intervention is still needed, but limitations in size and location are lessened.

- Motorized with sensors or a Building Automation System (BAS): These are configured to react to changing conditions, such as temperature, humidity and precipitation, and can integrate with existing systems. They require no human intervention.

The most effective way to utilize these openings in a mixed-mode ventilation system is to automate their operation with actuators and sensors linked to BAS systems. WindowMaster offers several industry-leading systems to manage the automation of actuators and motors in these systems.

LEED and WELL standards offer credits related to natural or mixed-mode ventilation as part of a whole building health strategy. Additional credits can be applied through daylighting, views, thermal comfort, and energy cost reduction.

Several relevant industry codes surrounding ventilation govern decisions made on this topic for many new construction projects. This includes:

- ANSI/ASHRAE 62.1 – 2019: Explains how natural ventilation rates should be calculated and the acceptable level of indoor air quality allowed.

- The California Title 24 Regulation, Building Energy Efficiency Standards: Explains requirements for the size of opening needed for a specific space.

- The International Energy Efficiency Code (IECC): Similar to ASHRAE code, but also provides information on “nighttime cooling.”

- The National Fire Protection Association Code (NFPA 5000): Endorses natural or mixed-mode ventilation for smoke control in certain instances.

If you are an architectural industry professional searching for AIA CE Credits, please consider taking Solar Innovations’ AEC Daily course on the topic of ventilation entitled, “Benefiting from Mixed-Mode Ventilation with Operable Skylights, Windows, and Doors.” While it covers many of the same topics mentioned here, it also outlines many other options and considerations involved in the topic as well as photographic examples.